ZYS provides high quality bearing products and professional bearing solutions for users in the fields of machine tool, wind power, metallurgy, automobile and rail transportation, construction machinery, etc. ZYS can perform batch production of various bearing products with inner diameter of 0.6mm to outer diameter of 6.8m. In addition to bearings, ZYS can also offer high-speed spindles, precision bearing instruments, bearing testing machines, bearing manufacturing machines and bearing parts.

ZYS precision angular contact ball bearings consist of high-precision angular contact bearings (standard series),super high-speed angular contact ball bearings,high-speed sealed angular contact ball bearings and high-speed spindle bearings.

In the metallurgical industry, the working environment of rolling mills, continuous casting machine or converters is really harsh. These conditions require bearings to withstand the harsh effects of heavy load, high temperature, dust and water. In order to meet the requirements of metallurgical industry, ZYS R & D teamhas developed bearings products with high quality, high precision and long service life and also can offer the bearing solutions for manufacturers in the metallurgical industry.

ZYS large-size heavy duty precision bearings are manufactured in our second industry park,which covers 133,333㎡ with total investment of 438 million RMB.

The inner ring,outer ring and rolling elements of bearing under normal working conditions are made of high carbon chromium bearing steel.To meet the special requirements,such as super high speed,wear-resisting,low temperature rising,long life and high reliability etc.,it’s suggested to use hybrid ceramic ball bearings.

ZYS has been committed to the research and development of bearings for rail transportation for a long time to meet the increasing requirements for rail transportation,such as higher speed,load,reliability and etc.

ZYS plays an leading role in aerospace bearing industry of China,We has successfully accomplished the bearing assemblies for “Dong fang hong” series man-made satellite,manned spacecraft series from “Shenzhou Ⅰ” to “Shenzhou Ⅹ”,“Chang’E” lunar exploration program,successful docking from “Shenzhou Ⅷ” and “Shenzhou Ⅸ” to Tiangong target aircraft.

ZYS automobile bearings include tapered roller bearings,cylindrical roller bearings,deep groove ball bearings and angular contact ball bearings,among which clutch bearings and the hub bearings units of the first,second and third generation are mainly used to gear box,axles,transmission system and other parts of all kinds of automobiles.We have conducted thorough research on wheel hub bearings,clutch release bearing,constant velocity cardan joint,gear box bearings and etc

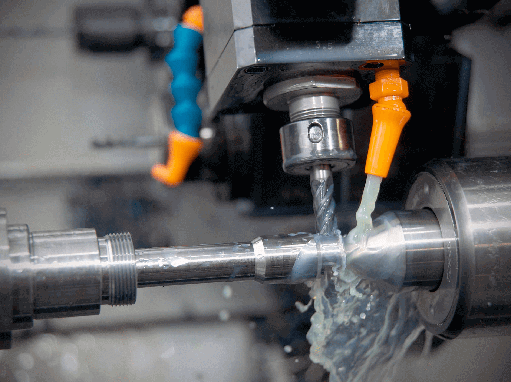

ZYS can supply batch production of various bearing manufacturing equipments,like CNC cutting equipments and automatic production line for bearing rings,automatic grinder,superfinishing machine,precision cold rolling machine for bearing rings,semi-automatic multi-purpose grinder for miniature ball bearing rings and other precision manufacturing equipments for bearing.

Besides all kinds of bearing products,bearing measuring machines are also our main products,which have been exported to India,Iran,Romania,Brazil and many other countries.Our main measuring machines include the instruments for measuring the dimension accuracy,roundness,profile and roughness of bearing parts,the instruments for inspecting bearing performance and other instruments used to automatically inspect and control various parameters during manufacturing process.These instruments are widely used in bearing workshops,inspection stations,measuring room and assembly factories.

ZYS has conducted in-depth research on bearing testing technology and reliability theory of all kinds of bearings,engaging in the development and manufacture of bearing testing equipments and undertaking the simulation testing,life testing and other performance tests for all kinds of bearings.We can also develop and manufacture the simulation testing machines in full-automatic control for the bearings used in various machineries (aviation,spaceflight,railway,automobile,motorcycle,machine tool,motor,etc.)

Since 1958, ZYS has been committed to the research and development of “high-tech, precise, cutting-edge, specialized and special” bearings, and relevant products. Our products have been used for mining, metallurgy, wind turbine generator, machine tool, machinery, medical treatment, automobile, rail transport, etc.

For industries relying on high-performance machinery, cylindrical roller bearings are a critical component. Known for their ability to carry heavy radial loads and operate at high speeds, these bearings are widely used in gearboxes, electric motors, pumps, and large-scale industrial equipment. However, even the most durable bearings require regular maintenance to prevent premature failure and unplanned downtime.Why Maintenance of Cylindrical Roller Bearings Is CrucialImproper maintenance is one of the leading causes of bearing failure. Regular inspections, proper lubrication, and early detection of wear can significantly extend the life of a cylindrical roller bearing and improve machine reliability.Key Maintenance Practices for Cylindrical Roller Bearings1. Regular InspectionVisual and mechanical inspections should be part of your routine maintenance schedule. Look for signs of:Excessive wear or pitting on rollers and racewaysDiscoloration indicating overheatingRust or corrosion from moisture exposureNoisy or rough rotation during manual turningUse tools like dial indicators, stethoscopes, and vibration analyzers to detect early-stage problems that are not visible to the naked eye.2. Proper LubricationLubrication is essential for reducing friction and preventing metal-to-metal contact. For cylindrical roller bearings, both grease and oil lubrication are common, depending on the application.Grease lubrication: Suitable for moderate-speed applications. Use high-quality lithium or synthetic-based greases.Oil lubrication: Recommended for high-speed or high-temperature environments. Regular oil analysis can help determine when replacement is needed.Always follow the manufacturer’s guidelines for lubrication intervals and quantities. Over-lubrication can be just as harmful as under-lubrication.3. Alignment and Fit ChecksMisalignment and poor fitting can cause uneven load distribution and accelerate bearing wear. During scheduled maintenance, verify that shafts and housings are correctly aligned and that the bearing fits are within tolerance.4. Clean Operating EnvironmentContamination from dust, dirt, or moisture is a major enemy of any bearing. Ensure that seals are intact and that the surrounding environment is clean. In harsh environments, consider using protective covers or shields.Common Symptoms of Bearing ProblemsUnusual noise or vibration during operationIncreased operating temperatureVisible signs of lubricant leakage or contaminationReduced machine performance or efficiencyWhen these symptoms appear, it's essential to take immediate action. Prolonged operation under faulty conditions can lead to complete failure of the cylindrical roller bearing and damage to connected components.How Often Should You Maintain Cylindrical Roller Bearings?The frequency of maintenance depends on the application, load conditions, and operating environment. For example:High-speed machinery: inspect weeklyHeavy-load, low-speed equipment: inspect monthlyNormal industrial use: inspect every 3–6 monthsAlways refer to the OEM’s maintenance schedule and adjust based on real-world operating conditions.ConclusionMaintaining cylindrical roller bearings is not just a technical necessity — it's a strategic decision to increase productivity, reduce costs, and minimize downtime. By implementing a regular maintenance routine that includes inspection, proper lubrication, alignment checks, and contamination control, you ensure the long-term health of your equipment.Need help choosing the right cylindrical roller bearing or setting up a maintenance schedule? Contact our technical team for expert advice tailored to your application.

2026-01-12 15:27:46 move

Expert Guide to Cylindrical Roller Bearing Maintenance

2026-01-12 15:27:46For industries relying on high-performance machinery, cylindrical roller bearings are a critical component. Known for their ability to carry heavy radial loads and operate at high speeds, these bearings are widely used in gearboxes, electric motors, pumps, and large-scale industrial equipment. However, even the most durable bearings require regular maintenance to prevent premature failure and unplanned downtime.Why Maintenance of Cylindrical Roller Bearings Is CrucialImproper maintenance is one of the leading causes of bearing failure. Regular inspections, proper lubrication, and early detection of wear can significantly extend the life of a cylindrical roller bearing and improve machine reliability.Key Maintenance Practices for Cylindrical Roller Bearings1. Regular InspectionVisual and mechanical inspections should be part of your routine maintenance schedule. Look for signs of:Excessive wear or pitting on rollers and racewaysDiscoloration indicating overheatingRust or corrosion from moisture exposureNoisy or rough rotation during manual turningUse tools like dial indicators, stethoscopes, and vibration analyzers to detect early-stage problems that are not visible to the naked eye.2. Proper LubricationLubrication is essential for reducing friction and preventing metal-to-metal contact. For cylindrical roller bearings, both grease and oil lubrication are common, depending on the application.Grease lubrication: Suitable for moderate-speed applications. Use high-quality lithium or synthetic-based greases.Oil lubrication: Recommended for high-speed or high-temperature environments. Regular oil analysis can help determine when replacement is needed.Always follow the manufacturer’s guidelines for lubrication intervals and quantities. Over-lubrication can be just as harmful as under-lubrication.3. Alignment and Fit ChecksMisalignment and poor fitting can cause uneven load distribution and accelerate bearing wear. During scheduled maintenance, verify that shafts and housings are correctly aligned and that the bearing fits are within tolerance.4. Clean Operating EnvironmentContamination from dust, dirt, or moisture is a major enemy of any bearing. Ensure that seals are intact and that the surrounding environment is clean. In harsh environments, consider using protective covers or shields.Common Symptoms of Bearing ProblemsUnusual noise or vibration during operationIncreased operating temperatureVisible signs of lubricant leakage or contaminationReduced machine performance or efficiencyWhen these symptoms appear, it's essential to take immediate action. Prolonged operation under faulty conditions can lead to complete failure of the cylindrical roller bearing and damage to connected components.How Often Should You Maintain Cylindrical Roller Bearings?The frequency of maintenance depends on the application, load conditions, and operating environment. For example:High-speed machinery: inspect weeklyHeavy-load, low-speed equipment: inspect monthlyNormal industrial use: inspect every 3–6 monthsAlways refer to the OEM’s maintenance schedule and adjust based on real-world operating conditions.ConclusionMaintaining cylindrical roller bearings is not just a technical necessity — it's a strategic decision to increase productivity, reduce costs, and minimize downtime. By implementing a regular maintenance routine that includes inspection, proper lubrication, alignment checks, and contamination control, you ensure the long-term health of your equipment.Need help choosing the right cylindrical roller bearing or setting up a maintenance schedule? Contact our technical team for expert advice tailored to your application.

move

How to Install Cylindrical Roller Bearings Correctly: A Step-by-Step Guide

2026-01-05 15:18:51Cylindrical roller bearings are widely used in industrial applications due to their high radial load capacity and low friction performance. However, to ensure optimal functionality and longevity, proper installation is essential. In this article, we’ll walk you through the installation process, highlight common mistakes to avoid, and share expert tips for achieving the best results.Why Proper Installation MattersImproper installation of cylindrical roller bearings can lead to premature failure, increased vibration, and operational inefficiency.Preparation Before InstallationCleanliness is critical: Ensure that the housing, shaft, and bearing itself are free from dirt, dust, or any contamination.Check shaft and housing tolerances: Verify that the dimensions conform to the recommended fits for cylindrical roller bearings.Use personal protective equipment (PPE): Gloves and eye protection should be worn to ensure safety.Installation MethodsThere are two primary installation methods depending on the bearing type and application: cold mounting and hot mounting.1. Cold MountingThis method is suitable for smaller cylindrical roller bearings. Use a bearing fitting tool or press to apply even pressure to the bearing’s ring being fitted.Apply pressure only to the ring being mounted.Never strike the bearing directly with a hammer.Use suitable sleeves and tools that match the bearing dimensions.2. Hot MountingFor larger cylindrical roller bearings, thermal expansion helps ease installation. Induction heaters are commonly used for controlled and safe heating.Heat the bearing to 80–100°C (176–212°F), but do not exceed 120°C (248°F).Use an induction heater with automatic demagnetization to prevent residual magnetism.Slide the bearing onto the shaft quickly and let it cool in position.Post-Installation ChecksEnsure the bearing is seated correctly with no misalignment.Rotate the shaft by hand to check for smooth motion.Lubricate according to the bearing manufacturer’s specifications.Common Mistakes to AvoidInstalling bearings with dirty tools or in contaminated environments.Applying force to the wrong ring during mounting.Overheating the bearing during hot mounting.Skipping the dimensional inspection of shafts and housings.ConclusionInstalling a cylindrical roller bearing correctly is crucial for ensuring performance, safety, and longevity in your machinery. By following proper procedures and using the right tools, you can significantly reduce the risk of early bearing failure. Always refer to the bearing manufacturer's guidelines for specific installation instructions and use certified tools for the job.If you're looking for high-quality cylindrical roller bearings or need technical support, feel free to contact our team. We’re here to help you keep your operations running smoothly.

move

The Difference Between Cylindrical Roller Bearing and Taper Roller Bearing

2025-12-29 13:07:56When selecting the right bearing for your equipment, understanding the structural and functional differences between various bearing types is essential. Two commonly used types in industrial applications are cylindrical roller bearings and tapered roller bearings. While they may appear similar at first glance, each has unique advantages and is designed for specific load and motion requirements.1. Structural DifferencesCylindrical roller bearings use cylinders as rolling elements, which are in linear contact with the raceways. This design allows them to carry heavy radial loads and operate at high speeds. The rollers are guided by either ribs on the inner or outer ring, depending on the design. These bearings are typically separable, making installation and removal easier.In contrast, tapered roller bearings feature conical rollers and raceways. The tapered design enables them to handle both radial and axial loads simultaneously. The greater the angle of the contact line, the higher the axial load capacity.2. Load Capacity and DirectionOne of the major distinctions lies in the direction of load that each bearing type can support. Cylindrical roller bearings are primarily designed to carry radial loads—the force perpendicular to the shaft. They are not well-suited for axial loads unless used in specific configurations.Taper roller bearings, on the other hand, are capable of handling both radial and axial loads. This dual-load capacity makes them ideal for applications where axial force is a significant factor, such as in automotive wheel hubs or gearboxes.3. Speed CapabilitiesDue to their design, cylindrical roller bearings generally have higher speed ratings compared to taper roller bearings. The line contact and minimal sliding friction allow for better performance in high-speed environments, such as electric motors or turbines.Tapered roller bearings have more contact area due to their angled design, which can increase friction and reduce speed capabilities. However, they compensate for this with superior thrust load handling.4. ApplicationsCylindrical roller bearings are commonly used in applications where high radial load capacity and high-speed performance are required. This includes electric motors, compressors, gearboxes, wind turbines, and machine tool spindles.Tapered roller bearings are widely used in automotive applications (especially in wheel hubs), heavy machinery, agriculture equipment, and mining machinery where both radial and axial loads are present.5. Installation and MaintenanceSince cylindrical roller bearings are usually separable, their installation and inspection can be simpler, especially in tight assemblies. However, it’s crucial to ensure proper alignment to avoid premature wear.Taper roller bearings require careful adjustment of the internal clearance during installation. Improper preload can lead to friction, overheating, and reduced lifespan.ConclusionChoosing between a cylindrical roller bearing and a taper roller bearing depends on your specific application requirements. If your system involves high radial loads and speed, cylindrical roller bearings are often the better choice. For applications where both axial and radial loads are present, tapered roller bearings offer better performance and durability.Understanding these technical distinctions will help you make informed decisions and improve the efficiency and longevity of your equipment.Need help choosing the right bearing for your project? Contact our technical team for expert advice on cylindrical roller bearings and more.

move