Products Catalog

- Bearings

- Petroleum Machinery Bearings

-

Precision Bearings

- High precision angular contact ball bearings

- High-speed sealed angular contact ball bearings

- Double-direction angular contact thrust ball bearings

- High-speed angular contact thrust ball bearings

- Ball screw support bearings

- Hybrid Ceramic Ball Bearings

- Cylindrical Roller Bearings

- Precision tapered roller bearings

- Turbo-charger bearing

- YRT bearings

- Four point contact ball bearings

- Thin section bearings

- Cross roller bearings

- Dental bearings

- Slewing Bearings

- Wind Turbine Bearings

- Bearings For Rolling Mills

- Bearings For Rail Transportation

- Automotive Bearings

- Hydrodynamic Bearings

- One-way Bearings

- Spherical Roller Bearings

- Standard Ball Bearings

- Taper Roller Bearings

- Spindles

- Precision Bearing Instruments

- Bearing Parts Measuring Instruments

- Finished Bearing Measuring Instruments

- Air-floating And Dense-ball Spindles

- Induction Heaters

- Degaussing Equipment

- Bearing Testing Machines

- Bearing Manufacturing Machines

- Bearing Relevant Materials

- ZYS Bearing Steel

- Bearing Ball Series Products

- Bearing Antirust lubricating Oil And Grease

- Bearing Cage Materials

- Abrasion-resistant Materials

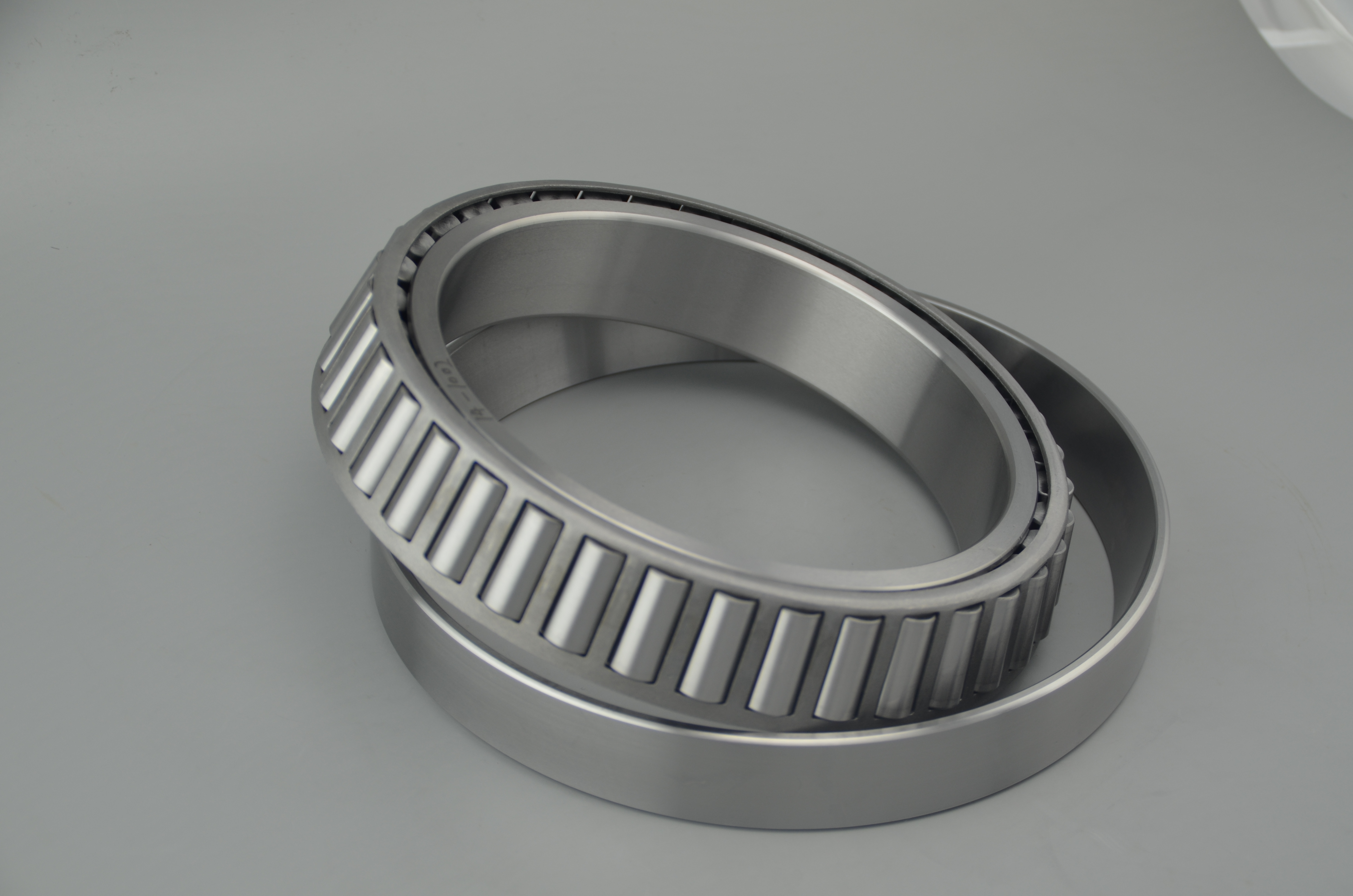

Precision tapered roller bearings

Description

ZYS offers a full range of ball bearings, roller bearings and plain bearings ranging from inner diameter of 0.6mm to outer diameter of 6.8m. We boast a large inventory and high-quality products.

Precision tapered roller bearings

ZYS single row tapered roller bearings can support radial load and axial load in one direction. The axial component force will be generated under the radial load, therefore, this bearing is often used with another tapered roller bearing in conjunction. Taper roller bearings can bear large axial load, but its speed performance is low. In addition, due to the separable inner and outer ring, mounting and dismounting tapered roller bearing are very convenient.Tapered roller bearings have tapered inner ring and outer ring raceways, and tapered rollers are arranged between the two rings. The projection lines of all conical surfaces converge at the same point on the bearing axis. This design makes tapered roller bearings particularly suitable for the combined load of radial and axial loads. The axial load capacity of taper roller bearing is mostly determined by the contact angle α; the larger the angle α, the higher the axial load capacity. The size of the angle is expressed by the calculation factor e; the greater the value of e, the greater the contact angle, the greater the applicability of the bearing to bear axial loads.This type of bearing is divided into single row, double row and four row tapered roller bearings according to the number of roller rows.Tapered roller bearings are widely used in automotive, rolling mill, mining, metallurgy, plastic machinery and other industries.The most commonly used taper roller bearings in machine spindles are ZYS 32000 dimension series.

Features of ZYS tapered roller bearings:

1. Bearing inner and outer ring Made of high-quality bearing steel raw materials. With advanced heat treatment process, it effectively extended bearing service life.

2. Rolling body With optimized design of rolling surface number curve, higher reliability and stronger bearing capacity can be achieved.

3. Bearing cage The stamped steel plate material effectively reduces the frictional heat between the rolling elements and the load is evenly stressed.