ZYS provides high quality bearing products and professional bearing solutions for users in the fields of machine tool, wind power, metallurgy, automobile and rail transportation, construction machinery, etc. ZYS can perform batch production of various bearing products with inner diameter of 0.6mm to outer diameter of 6.8m. In addition to bearings, ZYS can also offer high-speed spindles, precision bearing instruments, bearing testing machines, bearing manufacturing machines and bearing parts.

ZYS precision angular contact ball bearings consist of high-precision angular contact bearings (standard series),super high-speed angular contact ball bearings,high-speed sealed angular contact ball bearings and high-speed spindle bearings.

In the metallurgical industry, the working environment of rolling mills, continuous casting machine or converters is really harsh. These conditions require bearings to withstand the harsh effects of heavy load, high temperature, dust and water. In order to meet the requirements of metallurgical industry, ZYS R & D teamhas developed bearings products with high quality, high precision and long service life and also can offer the bearing solutions for manufacturers in the metallurgical industry.

ZYS large-size heavy duty precision bearings are manufactured in our second industry park,which covers 133,333㎡ with total investment of 438 million RMB.

The inner ring,outer ring and rolling elements of bearing under normal working conditions are made of high carbon chromium bearing steel.To meet the special requirements,such as super high speed,wear-resisting,low temperature rising,long life and high reliability etc.,it’s suggested to use hybrid ceramic ball bearings.

ZYS has been committed to the research and development of bearings for rail transportation for a long time to meet the increasing requirements for rail transportation,such as higher speed,load,reliability and etc.

ZYS plays an leading role in aerospace bearing industry of China,We has successfully accomplished the bearing assemblies for “Dong fang hong” series man-made satellite,manned spacecraft series from “Shenzhou Ⅰ” to “Shenzhou Ⅹ”,“Chang’E” lunar exploration program,successful docking from “Shenzhou Ⅷ” and “Shenzhou Ⅸ” to Tiangong target aircraft.

ZYS automobile bearings include tapered roller bearings,cylindrical roller bearings,deep groove ball bearings and angular contact ball bearings,among which clutch bearings and the hub bearings units of the first,second and third generation are mainly used to gear box,axles,transmission system and other parts of all kinds of automobiles.We have conducted thorough research on wheel hub bearings,clutch release bearing,constant velocity cardan joint,gear box bearings and etc

ZYS can supply batch production of various bearing manufacturing equipments,like CNC cutting equipments and automatic production line for bearing rings,automatic grinder,superfinishing machine,precision cold rolling machine for bearing rings,semi-automatic multi-purpose grinder for miniature ball bearing rings and other precision manufacturing equipments for bearing.

Besides all kinds of bearing products,bearing measuring machines are also our main products,which have been exported to India,Iran,Romania,Brazil and many other countries.Our main measuring machines include the instruments for measuring the dimension accuracy,roundness,profile and roughness of bearing parts,the instruments for inspecting bearing performance and other instruments used to automatically inspect and control various parameters during manufacturing process.These instruments are widely used in bearing workshops,inspection stations,measuring room and assembly factories.

ZYS has conducted in-depth research on bearing testing technology and reliability theory of all kinds of bearings,engaging in the development and manufacture of bearing testing equipments and undertaking the simulation testing,life testing and other performance tests for all kinds of bearings.We can also develop and manufacture the simulation testing machines in full-automatic control for the bearings used in various machineries (aviation,spaceflight,railway,automobile,motorcycle,machine tool,motor,etc.)

Since 1958, ZYS has been committed to the research and development of “high-tech, precise, cutting-edge, specialized and special” bearings, and relevant products. Our products have been used for mining, metallurgy, wind turbine generator, machine tool, machinery, medical treatment, automobile, rail transport, etc.

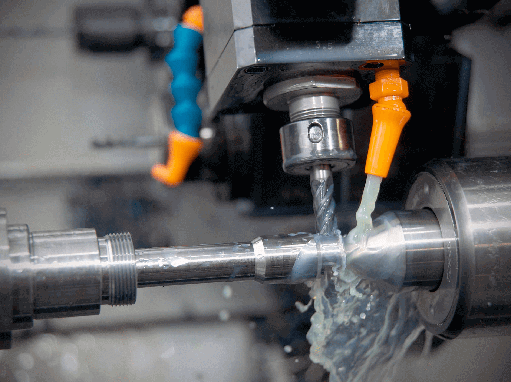

Question: What is the general task of turning rolling bearing rings?Answer: The main tasks of general turning of rolling bearing rings are: 1. For general forging blanks, remove the hard oxide layer on the surface.2. For bars and tubes, remove excess metal.3. Obtain the shape, size and position accuracy of turning processing.4. Leave a certain depth of allowance evenly on the surface to be processed. 5. Process the auxiliary surfaces (chamfers, grooves, slots, etc.).

2024-12-04 15:28:18 move

Technical FAQ

2024-12-04 15:28:18Question: What is the general task of turning rolling bearing rings?Answer: The main tasks of general turning of rolling bearing rings are: 1. For general forging blanks, remove the hard oxide layer on the surface.2. For bars and tubes, remove excess metal.3. Obtain the shape, size and position accuracy of turning processing.4. Leave a certain depth of allowance evenly on the surface to be processed. 5. Process the auxiliary surfaces (chamfers, grooves, slots, etc.).

move

Common Materials for Rolling Mill Bearings

2024-11-26 16:59:43Rolling mills are critical equipment in industries such as steel, aluminum, and other metal manufacturing. Bearings in rolling mills play a vital role in ensuring smooth operation under extreme conditions such as high loads, high speeds, and elevated temperatures. The material used in rolling mill bearings is crucial for their performance, durability, and ability to withstand demanding operating conditions. This article explores the common materials used in rolling mill bearings and their specific properties.Common Materials for Rolling Mill Bearings1. High-Carbon Chromium Steel (GCr15 or Equivalent)High-carbon chromium steel, often referred to as GCr15 (equivalent to 52100 in AISI standards), is one of the most commonly used materials for rolling mill bearings. This material offers excellent properties for high-load and high-speed applications.Properties: High hardness after heat treatment, which provides excellent wear resistance. Superior fatigue strength for withstanding repetitive stress cycles. Good dimensional stability under high temperatures. Cost-effective and widely available. Applications: Used in rolling mill applications where moderate heat and wear resistance is sufficient. Suitable for bearings in support rollers, guide rollers, and backup rollers. 2. Case-Hardened SteelCase-hardened steel is another popular material for rolling mill bearings. Unlike through-hardened steel, case-hardened steel has a hard outer surface and a tough, ductile core, making it ideal for applications where impact resistance is essential.Properties: The hard outer layer resists wear, while the soft core absorbs shock and impact. Improved resistance to cracking under heavy loads. Long fatigue life under challenging operating conditions. Applications: Suitable for bearings in heavy-duty rolling mills where high impact loads are common, such as hot rolling mills. 3. Bainitic SteelBainitic steel is a specialized material known for its excellent toughness and wear resistance. It is often used in rolling mill bearings that operate in extreme conditions.Properties: Excellent thermal stability, making it suitable for high-temperature environments. High toughness to resist cracking and deformation under heavy loads. Superior wear resistance compared to standard bearing steels. Applications: Ideal for bearings in hot rolling mills and continuous casting machines where high temperatures and heavy loads are prevalent. 4. Stainless SteelStainless steel is used in rolling mill bearings that require high corrosion resistance due to exposure to water, chemicals, or other corrosive environments.Properties: Excellent corrosion resistance, even in wet or chemically aggressive conditions. Moderate load and wear resistance compared to chromium or bainitic steels. Suitable for environments with high humidity or cooling water exposure. Applications: Bearings in rolling mills used for aluminum or other non-ferrous metals, where cooling water or corrosive environments are common. 5. Special Alloy SteelsCustom alloy steels are often developed for rolling mill bearings to meet specific demands, such as extreme temperature resistance or improved fatigue performance. These materials may include added elements like molybdenum, vanadium, or nickel to enhance particular properties.Properties: Tailored to provide a balance of hardness, toughness, and thermal stability. Enhanced fatigue and wear resistance for demanding applications. Ability to perform well under both high loads and temperatures. Applications: Used in high-performance rolling mills such as tandem mills or heavy plate mills.

move

GLESI Chief Engineer Li Heng and his team visited ZYS for exchange

2024-11-20 13:43:19On November 19, Li Heng, chief expert of SINOMACH and chief engineer of Guilin Electrical Equipment Scientific Research Institute Co., Ltd., and his team visited the company for research and exchange. Li Wenchao, deputy general manager and chief engineer of ZYS, and Sun Xiaobo, general manager of the manufacturing service division, also participated in the exchange. Li Wenchao introduced the company's development history, scientific research strength, production and operation, and Li Heng spoke highly of the company's achievements in technology research and development and business. The two sides conducted in-depth discussions on key issues such as the test plan, performance requirements, and product schedule of the "wear-resistant slider". Both parties expressed that they will strengthen communication and exchanges in the future to develop new growth points for cooperation and new highlights of the industry in areas such as resin raw materials and insulating materials to achieve win-win cooperation. Li Heng and his party also visited the "wear-resistant slider" production line and expressed full recognition of the processing methods and production processes.

move